technologies

breeding of.......

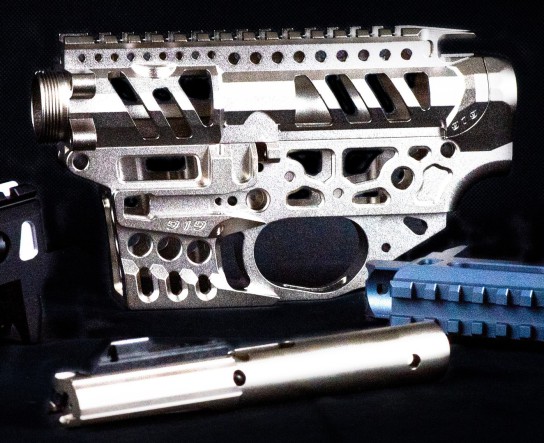

"schoger inside" custom gun parts - built to win -

100% engineered & crafted in bavaria

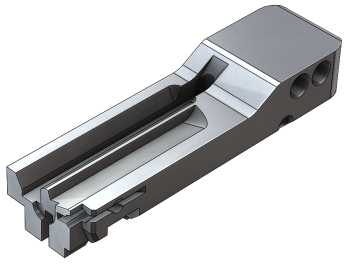

R-bolt TT®-ta-C coated for the 919® madass

- coating structure hydrogen-free tetrahedral amorphous carbon

- surface hardness appx 7000 HV

- outstanding wear & friction properties

- coating thickness appx 1.0 μm

T-bolt titanium nitride coated

- coating structure monolayer PVD

- surface hardness appx 2500 HV

- outstanding wear & friction properties

- coating thickness appx 1.0 μm

moab - the mother of all bolts

- incredible colours

- dirt-repelling slick surfaces

- 100% reliable dry operations guaranteed

- outstanding tribological properties

- maximum hardness adjustable to almost 7000 HV

works perfect with your appropriate Speed Doctor® PVD-coated firing pin

- tinpin9 titanium nitride coating

- tacpin9 tetrahedral amorphous carbon coating

3.3 splitmaster

smooth operator buffer system for .223 and 9mm systems

radical race receiver for the 919 series

#2 nickel hi-phos coated receivers and bolts

#8 bnb black nickel bitch lo-phos coated receivers

GEN2 RR high precision receiver & 1522 chassis for the 11er & wyldthing series

3SL short stroke superlight cobolt

coming soon:

last round up for 2023 was the 11#22boltbox project

receivers bolts & charging handles for the german rimfire series

this fast&furious "krautstuff" is 100% MADE IN BAVARIA

we have a premium selection of heavy duty extractors & firing pins built in

the GEN2 hot section for the 11er & wyldthing series is ready to race

nice low weight skeletonized 7075 high precision billet receivers....

....with metric threads & bolts......

the german rimfire bolts will be available as well with TIN or DLR -diamond like rainbow- coating

3SL cobolt is the short stroke superlight competition bolt

nice looking supersmooth & superfast cycling

everybody is going crazy for the "fuzzybar" charging handles......surprise surprise.......

SANTA CLAUS proudly presents our brand new 2024 FUZZYBAR charging handles:

low weight 7075 billet charging handles for fast & reliable bolt cycling

delivered as a complete tuning kit

2 sizes regular or xs available

polished & hardened spring guide rod

2 different recoil springs

reduced trigger hammerspring

2 different recoil buffers included

weight balancing with 10mm grub screws

offering all the tuning options required for low speed competition ammo

nice colours available: #2ICN ; #3RHC ; #4FGB ; #10UFO ; #11CBS

service recommendations:

due to the extreme low weight of the guns, they have a slight tendency to be ammo-sensitive

especially at low temperatures, we strictly recommend to keep your ammo warm and cozy

this is concerning mostly .22 & 9mm subsonic ammo

we have special "slowmow" buffer or recoil rod springs available

or just switch to the brand new FUZZYBAR charging handles in combination with a 3SL cobolt

extractors and firing pins should be checked and changed on a regular basis, minimum once a year

we clean&lube our sweeties with CICO® GUNSPRAY GS77 from Triooo® Innovations, nice stuff from outer space